Ad Details

-

Added: April 16, 2020

-

Condition: new

-

Location: United States

-

State: Washington

-

City: All

-

Views: 220

Description

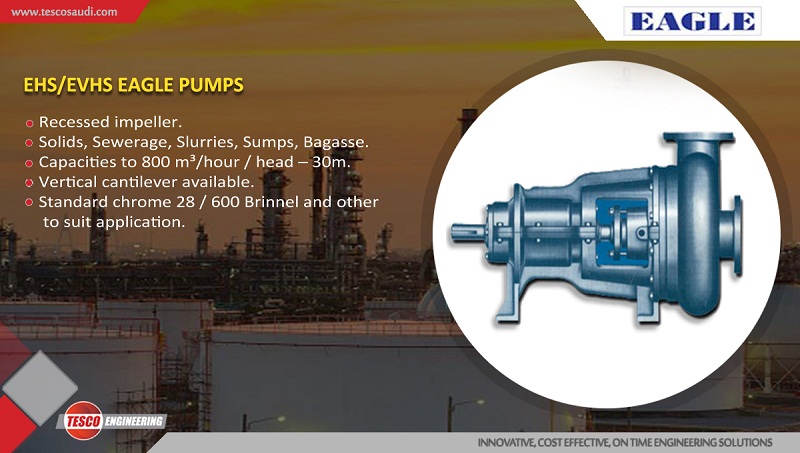

TESCO Engineering represents Eagle Pumps in Saudi. Eagle range of pumps offer cost effective, reliable, high quality pumps for all types of pumping applications, from minimal processing, the power industry and general industry.

our service

WORKSHOP FACILITY

TESCO Engineering’s wrokshop facility is situated in the heart of Jubail Industrial City. Here we focus on pump refurbishment; mechanical seal refurbishment for all types of mechanical seals, retrofitting of bearing isolators for equipment which is not achieving the desired (MTBF) targets; refurbishment and testing; milling; turning; fabrication; arc welding; TIG welding; drilling; cutting; breakdown repairs; and the maintenance and cleaning of Vahterus Plate and Shell Heat exchangers, along with general maintenance.

TESCO Engineering also offers fault finding at site, route cause analysis and report writing services, along with the ability of offering industrial plants, a full service long term maintenance contract for the reliable operation of our client’s rotating equipment.

Our application engineering department is also able to reverse engineer critical rotating equipment components to OEM specifications to avoid downtime of your rotating equipment. These repairs ensure extended mean time between failure (MTBF) and help to reduce total cost of ownership.

With our trained, experienced technicians, TESCO Engineering’s goals are to provide the highest level of service to our clients in the industry.

MECHANICAL SEAL REFURBISHMENT

TESCO Engineering gives new life to a seal that is no longer performing in the field. Our quality control process produces a mechanical seal that is both precision tested and reliable.

We have made a commitment to repair all brands and mechanical seal types regardless of manufacturer. Our repair facility is one-of-a kind.

We repair to “like-new” condition. If the seal is not repairable, we will quote a new Trem Engineering seal as replacement. We also offer a range of swop-out or exchange programs to suit the customer’s needs. We have designed the repair facility to combine state of-the-art engineering and manufacturing capabilities. We view this commitment as a necessity to properly service our end users in today’s market. Each seal component is decontaminated and evaluated in detail: faces, secondary seals and bellows testing, metallurgical examination, and critical dimensions evaluation.

Longer Service Life For Mechanical Seals

Fast Economical Repair Service

TESCO Engineering gives you exactly what you are looking for in a seal repair service – Quality, Flexibility, Quick Response and Technical Assistance.

Download and view a mechanical seal inspection report

WHAT DOES TESCO DO WITH YOUR SEALS?

Completely disassemble the seal.

• Clean all parts ultrasonically, sand blast with micro granules and inspect for damage.

• Compile mechanical seal inspection report and provide to the client, RSA available on request.

• Lap and polish the recoverable sealing faces.

• During and after the lapping we inspect the flatness of the seal faces with monochromatic light to one light band.

• Replace elastomers and other parts that no longer meet the specification.

• Reassemble and pressure test your mechanical seal.

• Protectively package and dispatch back to you.

PUMP REPAIR DIVISION

TESCO Engineerings pumps repair and services division has a well-equipped workshop in Jubail Industrial City Saudi Arabia. We offer an on-site service as well as an in-house service when it comes to repairing or the retro fitting of pumps and rotating equipment. Our highly trained technicians will also do on-site fault finding and report writing. TESCO Engineering’s Pump Division can also offer you the client technical advice in the selection of the pumps needed for your process. We will also assist with the installation process and the commissioning and startup of any new installations. TESCO Engineering is currently representing Zeilfelder Pumpen and KRAL.

SCOPE OF WORKS FOR PUMP REPAIRS

Disconnect pump from pipework and drive coupling or Pump can be collected at customer site.

The pump is carefully disassembled and all critical clearances and dimensions are recorded. Pump technician will inspect all the pump parts.

Upon completion of the inspection, TESCO Engineering will submit a pump report with a detailed scope of work for the repairs as well as a firm quotation for the costs associated with the pump repair.

Feedback to the client will be submitted via E-mail.

After receipt of the order, all components are then prepared for bead blasting and cleaning, the repair begins and all components requiring repairs are meticulously replaced or reverse engineered to the necessary tolerances.

Mechanical seal will be tested on our test rig before being installed back on the pump shaft.

The pump re-assembled back to the original equipment manufacturer’s specifications and resprayed.

Pump and mechanical seal is tested for any leaks.

Pump is delivered to the client.

VAHTERUS PLATE AND SHELL HEAT EXCHANGER SERVICING

Vahterus Plate & Shell Heat Exchangers are fully cleanable and easy to maintain. There are various cleaning options, depending on the fouling material, which TESCO Engineering’s trained and experienced technicians offer from our workshop in Jubail or on-site at your plant. These services include:

• Mechanical Cleaning ( High Pressure Water Jetting) • Chemical Cleaning • Steam Cleaning • Back Flushing • Soda Blasting • Pyrolysis • Ultrasonic Cleaning.

The entire cleaning process is much quicker and cost effective when compared to other heat exchanger technologies. All cleaning is governed by a Quality Control Plan and a post cleaning report is issued for every unit cleaned. Please see the below link for more information on cleaning and maintenance of Vahterus Plate & Shell Heat Exchangers.